how to do hardness test|hardness test methods : distributing There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an . WEBHome; Contact .

{plog:ftitle_list}

ClickShip provides all the tools you need to streamline your entire shipping process and optimize order fulfillment to save you valuable time and money. Better Shipping. Better Pricing. No matter what type of online business you are operating, there is a plan that is suited for your business' needs. Every ClickShip plan includes a 14-day free .

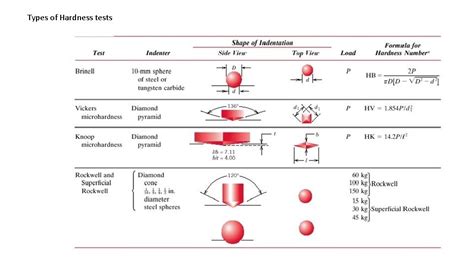

Hardness testing works by pressing a standardized, hard instrument into the material that is being tested. The instrument, called an indenter, is pressed into the sample for a standardized length of time (a .Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed.

types of hardness tests

There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined .Hardness Testing Considerations The following sample characteristics should be consider prior to selecting the hardness testing method to use: • Material • Sample Size • Thickness • Scale • Shape of sample, round, cylindrical, flat, irregular • Gage R & R Material The type of material and expected hardness will determine test method. Try to scratch the mineral with a copper penny. Work with the same mineral sample and get out a copper penny. The penny has a hardness level of 3 compared to the 2.5 hardness of your fingernail.

(4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity . Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. We depend on the data produced to verify heat treatment, structural integrity, and quality of components to determine if a material has the properties necessary to ensuring that the materials utilized in the .Brinell Hardness Test. You might have heard about this in school, that you can get a ball bearing, whack it with a hammer on a piece of metal with a known hardness, then whack it on the piece of metal in question, compare the diameters of the indents, and work out the hardness of the metal from the results. .

Water hardness test meters detect the number of solids dissolved in your water. Find the “On” button near the meter’s display and press it down for a few seconds. After 2-3 seconds, the display will light up and read “0.0” so you can start using the meter. So, being able to do a hardness test provides a quick technique to identify minerals. Mineral hardness is essential since it indicates minerals’ chemical composition and structure. Knowing the mineral hardness helps to narrow down a list of possible minerals during sample identification. The hardness tests can clearly distinguish between two .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly against the unknown, and deliberately drag it across the flat surface while pressing firmly. The choice of tool for a task can depend on the metal’s hardness. Knowing how to do hardness testing—more importantly, what the individual metal hardness testing method actually means—is important in choosing materials for a project and the tools that will cut and work that material, whether they are brittle materials or softer materials. .

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

How do you test your part’s hardness? Brinell Hardness Test. The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. The indentation diameter is then measured optically. How to do Rockwell Hardness Test. The first step that I always take when performing Rockwell hardness test is choosing either diamond cone indenter or hard steel ball depending on material which I want to test. The .

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the .💧 4 Methods to Test Water Hardness. There are several methods to test water hardness, ranging from simple DIY techniques to more accurate test kits. Here are the most common methods: 1. Soap Test. The soap test is a simple and cost-effective way to get an approximate idea of your water hardness.

ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .

The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is . The Mohs hardness scale rates the hardness of minerals based on their ability to scratch softer ones. The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer minerals. The scale isn’t perfect, but it’s a great tool for quick identification of rocks in the field. Choose a strategy based on the tolls and minerals available for the scratch test. Do a scratch test by scratching your unknown mineral by index mineral from the Mohs scale one by one. Do a scratch test by tools with equivalent hardness (fingernail – 2, copper – 3, a piece of glass, and a knife – 5 – 5.5, a steel file – 6 – 6.5). Another way to test water hardness is to do a visual inspection of anything your water comes into contact with. Check your sinks, bathtubs, utensils, plates, etc. Hard water produces an unmistakable crusty scale, particularly on faucets and on dishes. Well maintained water softeners will alleviate this crusty scale, along with the other .

The Leeb Hardness Test is one of these methods used to test a material’s hardness. The Leeb Hardness Test is a material-specific test. The Leeb Hardness Test tests determine if a material is suitable for specific applications and when a material is required to meet specification or performance requirements.In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. The Rockwell hardness of the test piece is calculated by subtracting . Rockwell hardness is determined by measuring the distance traveled by an indenter when a heavy load is applied to a heat treated part. Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part.

types of hardness testing methods

Introduction. When manufacturing metal components of any kind, it’s important to have control over the properties of a finished part. To ensure that your finished product meets all the necessary specifications, you might need to perform a Rockwell hardness test on a metal part or test sample at different points during production. It is useful to check the hardness of steel and . If your hard water test displays or produces the result in parts per million or milligrams per liter, you can take the total hardness level and divide it by 17.1 to determine the hardness in grains per gallon. For instance, if your hard water test shows 182 mg/L, you have 10.6 gpg. You can convert mg/L or ppm by dividing the total hardness by .

Digital Automatic Polarimeter service

types of hardness testers

WEBCdzinha é uma palavra que representa o abrasileiramento da expressão crossdresser. Assim, este texto etnográfico baseia-se na observação participante e na participação .

how to do hardness test|hardness test methods